Graco Equipment Selection Guide

Which system is right for you?

Whether you’re spraying polyurethane foam insulation in a home, commercial building or rooftop, or applying polyurea to coat a bedliner or a large containment field, Graco Reactor Plural-Component Proportioner Systems help you get the job done with superior results.

We have a large selection of plural component equipment packages designed for every application, from low to high output applications, and small to large projects. Graco proportioners feature the most advanced equipment technology in the industry. You’ll discover that Graco equipment is easy to use, rugged, reliable and easy to maintain.

We’re here to help

If you need help deciding which equipment package is right for your application we encourage you contact one of our sales experts, they are the best in the business at providing solutions that work.

Call Toll Free: 1-800-901-0088

High-production Systems

Overview

Graco’s line of hydraulic Reactors brings increased yield and performance to high-output spraying. Hydraulic systems are the choice of spraying professionals who want to reap the benefits of the latest spraying technologies and add productivity to boost their bottom line.

Features

- Top of the line system for high-production professionals

- Highest value for the greatest performance

- Output of up to 52 lb (23.6 kg) per minute

- Provides superior, uninterrupted performance

- Provides operator with material data and system diagnostics for total control

Spray Foam Machines

Coating Machines

Mid-production Systems

Overview

Equipped with material data and system diagnostics, Reactor proportioners provide total control. Advanced features provide longer equipment life, more uptime for your spray day and overall Graco reliability.

Features

- The most popular proportioning system

- Mid to high-output applications

- Output of up to 30 lb (13.6kg) per minute

- High value for great performance

- Provides operator with material data and system diagnostics for total control

Spray Foam Machines

Coating Machines

Mid/High-production Gusmer Systems

Overview

The Gusmer systems are simple and durable hydraulic spray machines designed with reliability and ease of service in mind. Gusmer's point-to-point wired electrical cabinet sits atop Graco's industry-proven Reactor 2 chassis, including the horizontal pump line, fluid heaters, and hydraulic system.

Features

- Economical Price Point

- Mid to high-output applications

- Point-to-point wired electrical cabinet

- Output of up to 45 lb (20.4kg) per minute

- Hydraulic Reactor 2 chassis

- Simple Controls for Ease of Use

Spray Foam Machines

Entry Level Systems

Overview

Great for entry-level light industrial manufacturing, construction and other field-related spraying jobs. Dependable motors deliver efficient and consistent operation. Designed to simplify the operator's job, optimize spray parameters and maximize productivity.

Features

- Entry-level proportioning system

- Low to med-output applications

- Output of up to 25 lb (11.4 kg) per minute

- Excellent value for residential and commercial use

- Maintains consistent output pressure for uniform spray pattern

Spray Foam Machines

Coating Machines

Portable & Touch-up Systems

Overview

The Reactor E-10 and E-10 HP sprayers are ideal for plural-component spray, joint-fill jobs and touch-ups. With smart controls that are easy to setup and simple to operate, the E-10 and E-10 HP are a natural complement to any proportioning equipment line-up.

Features

- Ideal for small to medium projects

- Portable, compact and easy to maneuver

- Easy to use

- Output of up to 12 lb (5.4 kg) per minute

- Fit through standard doorways and are easy to maneuver on the jobsite

- Minimal system feedback for operator

Spray Foam Machines

Coating Machines

Understand Spray Performance

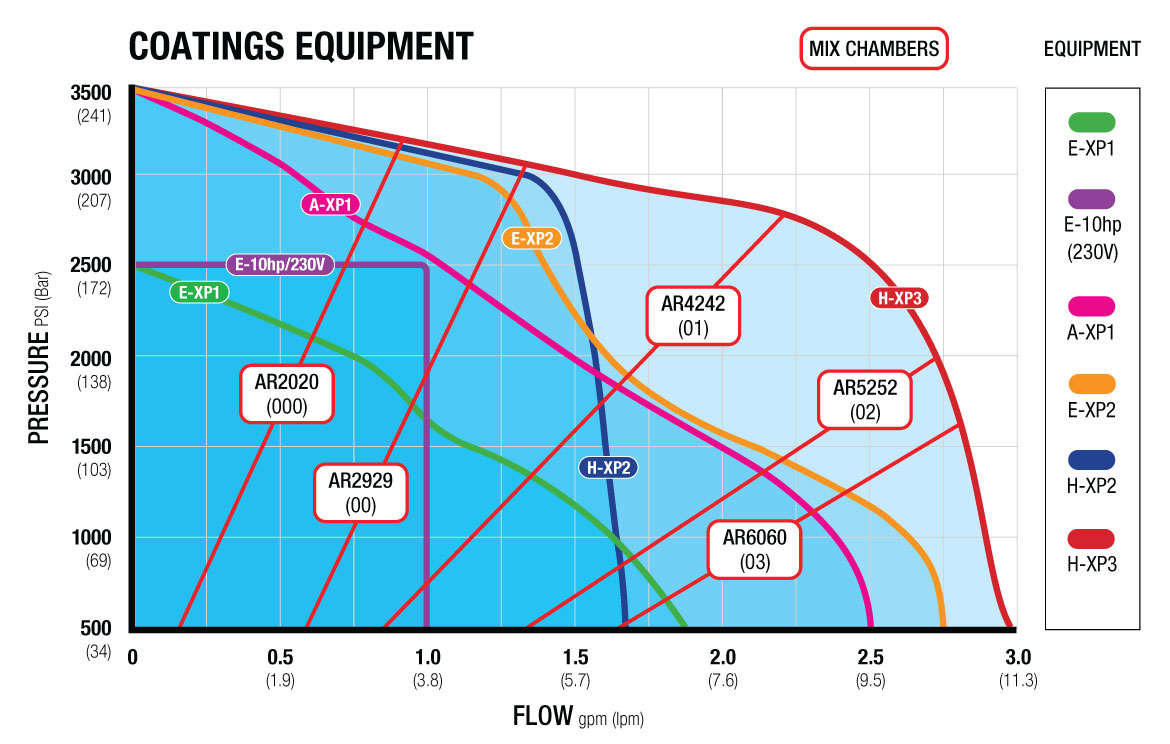

Performance charts with mix chamber choices

Use these charts to help identify the system that will work most efficiently with each mix chamber or desired flow rate.

How to use these charts

Start by selecting the required spray pressure, then select the desired flow rate. Use the chart to determine which equipment model will meet your requirements.

Flow rates are based on a material viscosity of 60 cps. Electric unit performance curves are based on typical spraying conditions. Periods of continuous spraying or very high ambient temperatures reduce the performance envelop. Hydraulic system performance curves allow for continuous spray conditions. *Output of a flat tip will be slightly less than the round equivalent.